His vision brings the French past into the present

Many large companies today rely on Columbus vacuum technology to produce extraordinary workpieces made of wood and wood-like materials. Quite a few of these companies, which now employ hundreds of people, once started out as one-person businesses.

In this blog we would like to state once again that Columbus is perfect for all people who want to define the limits of their possibilities solely through their own imagination, regardless of company size.

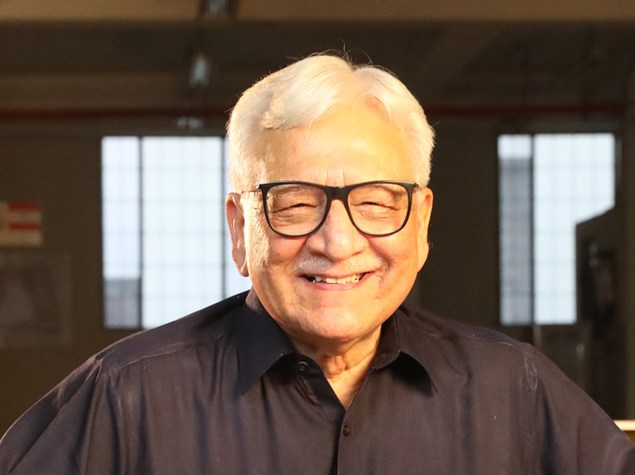

Our story is about Markus Kramer. The 27-year-old is a passionate carpenter and is now a master of his craft. As usual in the carpentry industry, Markus had to create a masterpiece in order to achieve the title. His vision for this has its roots in France's past. Because the piece that he finally made is based on an old French telephone cabinet from 1910.

Markus transformed this vision into the present and created a truly beautiful one-of-a-kind. In the manufacturing process, Markus Kramer made use of the many advantages of vacuum technology. So he used the Columbus vacuum bag Vacuflex to give his workpiece its characteristics through laminated bending, form-veneering and coating.

The main components of the cabinet, such as the top and bottom, are made of black through-dyed MDF, veneered with American walnut veneer using Vacuflex. The roller blind is also made of black MDF, which was also covered with 2 mm thick linoleum using Vacuflex. A black linen fabric is glued to the back. In addition, all 164 slats of the roller blind are fitted with a solid American walnut strip. The inner back wall consists of several layers of flexible plywood and veneer and was bent into shape with the help of a template in the vacuum bag. The drawers are solidly built and can be pulled out completely via a classic guide rail. All three drawers were made with finger joints.

As you can see, a vacuum bag, which is the inexpensive option for entering the world of vacuum technology, offers a wide range of possibilities. This gives you applications such as the laminated bending of wood to form curved workpieces, the veneering of curved parts or edges, but also the covering of wood with other materials.

We thank Markus Kramer for sharing his story and wish him all the best for the future.

In this blog we would like to state once again that Columbus is perfect for all people who want to define the limits of their possibilities solely through their own imagination, regardless of company size.

The master and his vision

Our story is about Markus Kramer. The 27-year-old is a passionate carpenter and is now a master of his craft. As usual in the carpentry industry, Markus had to create a masterpiece in order to achieve the title. His vision for this has its roots in France's past. Because the piece that he finally made is based on an old French telephone cabinet from 1910.

Markus transformed this vision into the present and created a truly beautiful one-of-a-kind. In the manufacturing process, Markus Kramer made use of the many advantages of vacuum technology. So he used the Columbus vacuum bag Vacuflex to give his workpiece its characteristics through laminated bending, form-veneering and coating.

Structure and manufacturing

The main components of the cabinet, such as the top and bottom, are made of black through-dyed MDF, veneered with American walnut veneer using Vacuflex. The roller blind is also made of black MDF, which was also covered with 2 mm thick linoleum using Vacuflex. A black linen fabric is glued to the back. In addition, all 164 slats of the roller blind are fitted with a solid American walnut strip. The inner back wall consists of several layers of flexible plywood and veneer and was bent into shape with the help of a template in the vacuum bag. The drawers are solidly built and can be pulled out completely via a classic guide rail. All three drawers were made with finger joints.

Masterful benefits

As you can see, a vacuum bag, which is the inexpensive option for entering the world of vacuum technology, offers a wide range of possibilities. This gives you applications such as the laminated bending of wood to form curved workpieces, the veneering of curved parts or edges, but also the covering of wood with other materials.

We thank Markus Kramer for sharing his story and wish him all the best for the future.

Interest?

We would be happy to inform you about the vacuum bag, your options, all versions, prices, etc.

Thank you very much for your inquiry!

We will get back in touch with you.

We will get back in touch with you.

INTERESTING BLOG ARTICLE

Realising Visions

Swiss Precision Meets Creative Design

Tailor-made perfection in Estonia

Haapsalu Uksetehase AS Manufactures Doors for Hampton by Hilton

Premium Interior Fittings and Yacht Furnishings

A Vacuum Press has supported Der Ernzerhof for many years

Outstanding Shopfitting with Vacuum

"außerdem" utilizes the advantages of a vacuum press by Columbus

Flat veneering with vacuum

The use of a vacuum press as a veneer press

Masterful craftsmanship

The Wardrobe for the Master Carpenter Exam

“It presses both flat and curved shapes”

Clairhout Interieur: A Revolution in Interior Design

Columbus customer creates artistic masterpiece

Advertisement for Jean Paul Gaultier in Santiago de Chile

Beautiful Gift Idea

My Esel – exceptional bicycles & e-bikes

Curving the Impossible with Columbus

Interwood sets new standards with the press

Infinity for bimobil motorhomes

Large-scale perfection for high-gloss paint

Precession and art from vacuum

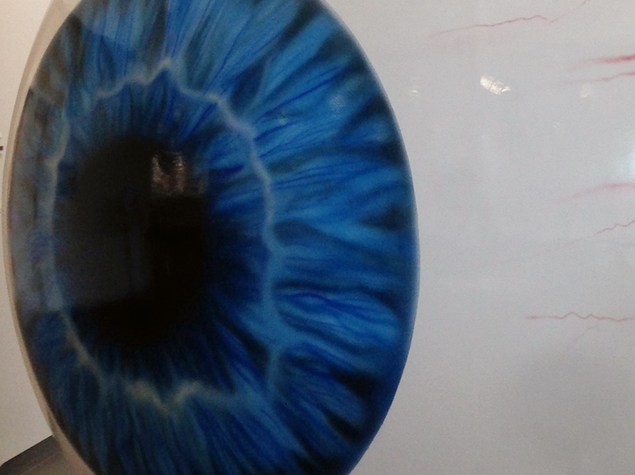

Impressive eye model for the university clinic

From the fruit bowl to the ceiling construction

The possible applications of a vacuum press

The Columbus Pressure Shifting Tool

So that natural rubber does not deform steel

Kempa from Belgium invests in 2 vacuum presses

Round & curved shapes for modern interior design

A patent for the modular system

Everyone said it doesn't work - I believed in it

Columbus: Tips and Tricks from Practice

Mold making for mold bonding with vacuum

A look behind the scenes at Columbus

Thank you Dad, for a wonderful journey with you

A look behind the scenes at Columbus

Günther Vetter - the invention of the vacuum bag

Protect your employees and your company

EU-mandated training for PUR hot melt adhesives

Skateboard ramps with the vacuum press Pioneer

Andreas Schützenberger does great things

Vacuum bag: ZOSIA by Robert Nößler

His masterpiece with nostalgia and a secret

What are the benefits of a vacuum press?

Not only to cover curved workpieces and veneer

Report: International Fair in May 2023

Great success at the LIGNA in Hanover

Vacuum bag: Modern Drop by Lars Hackl

Layer bonding for the next masterpiece

Vacuum bag: masterpiece by Tommy Kairat

First-class form veneering with Vacuflex

Forming of solid surface materials

Utilizing the great potential of a vacuum press

Vacuum pumps: an objective comparison

Columbus shows the advantages of dry runners

Free creativity in the creating process

Students from the Waldorfschule Mainz

1.5 weeks instead of 6 weeks production time

Precisely curved fronts of the DALI speakers

That was the Holz-Handwerk 2022

PIONEER and MOVE: Spectacular success at the fair

The magic lies in the perfect details

LL Installations creates high-quality accents

Handmade speakers from Denmark

One million satisfied DALI customers in over 70 countries

Columbus & University of Stuttgart

Artworks - Innovation meets Science

Independence from suppliers

6 Reasons to buy a Vacuum Press from Columbus

The Birth of Infinity Vacuum Press

Flexstone produces large parts for houseboats

Sound loungers - feel the music

Magnus Hoffmann has developed something creative

Excellence as far as the eye can see

Acoustic panels for the Leonardian Center in Australia

A dazzling cooperation between two pioneers

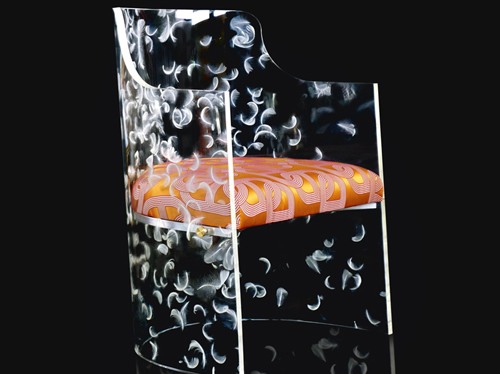

Vacuum - Acrylic glass - Unlimited possibilities

NOW: Individual. Exceptional. Unique.

Vacuum: Best performance from batch size 1

A compound better than wood

Resysta: Design meets sustainability

Vacuum bag: White River by Jannik Otte

Masterpiece as an eye-catcher for the entrance area

Young creativity conquers the world

Fascinating - these are students - not carpenters

Full speed ahead with a vacuum press

Tour buses for the biggest stars in the world

World premiere: acrylic glass chair

Customer Zöllner manufactures for Acrylic Couture

Columbus makes the impossible possible

VIDEO: Seamless veneering in just a few working steps

Columbus forms Kerrock in Belgium

An exceptional design future with vacuum presses

Exhibition builder Prager manufactures for Siemens

An innovative exhibition stand based on vacuum

New times bring new opportunities

Conquering existing markets with new applications

Columbus expands its global dealer network

GEWEMA membership for Columbus Vacuum Presses

That was the Holz 2019 in Basel

Columbus and the great Swiss carpenters

Cooperation with Schachermayer

Columbus receives another strong partner

Press: People talk about Columbus

What is published in professional circles about us

MEETING POINT NOBLE VENEER

Visiting the Schachermayer company

An Honor through Vacuum Technology

A chili as a creative lounge furniture is the winner

Hymer - a success story with vacuum

The well-known producer works with Columbus

The NDR works with a vacuum press

The Tagesschau desk was produced with Columbus

Why we are called what we are called

What Christopher Columbus has to do with Columbus